Professional mounting hardware buttons, eyelets, jeans buttons and rivet.

(This is not a book, and a brief overview of the equipment for installation metal fittings)

Types of presses for installation metal fittings:

- manual

- hand with the hammer mechanism

- Electromechanical

-pneumatic

- manual for ad banners

- Manual presses:

-Screw press D-1

The press applies only for covering buttons.

Pressing the nozzle is carried out by turning the knob with a spiral thread clockwise.

Width-85mm X 155mm. Height-mm.

Weight 4,2 kg (requires hard mount the press to the table top)

Production - Turkey

Similar press production - company "Big Accessories" Greece

Similar media manufacture of other companies:

Comments: When working with this press has a relatively small pressure, buttons made of thick fabric, type of cloth, can not be obtained. Also problematic to install on this press the metallic furniture.

For this type of media you want to hard mount the press to the table top, respectively, loss of mobility during operation.

- Press universal lever TER-1

Sets the button, eyelets, polyteny, jeans buttons, making pulling buttons and buttons. Fit all nozzles of Turkish production.

Dimensions: 95mm x 185mm. Height-315mm.

In the upper movable rod inch 6mm thread, at the bottom of the hole diameter 19 mm, with adapter with a diameter of 12 mm

Weight 4.4 kg

Production - Turkey

Comments:

The only drawback to a short handle, respectively, attached more effort when installing metal fittings.Аналогичный Production - company "Big Accessories" Greece

Art. – 9542

- Press universal lever TER-2

Sets the button, eyelets, rivet, jeans buttons, making pulling buttons and buttons. Fit all nozzles of Turkish production.

Dimensions: 90 x 180mm. Height 390mm.

In the upper movable rod inch 6mm thread, at the bottom of the hole diameter 19 mm, with adapter with a diameter of 12 mm

Weight 5,6 kg

Production - Turkey

- Press universal lever TER - 3

Sets the button, eyelets, rivet, jeans buttons, making pulling buttons and buttons. Fit all nozzles of Turkish production. Inch thread.

The weight of 4.9 kg

Production - Turkey

Comments: most Likely this is the Lite version of TER-2

- Press universal lever СЕМ (CETINKAYA MAKINA)

Sets: eyelets, eyelet, rivets, all kinds of buttons, making pulling buttons and buttons. Fit all nozzles of Turkish production. Inch thread.

Weight - 4,56 kg

Production - Turkey

Comments: Excellent choice.

- Press universal lever СЕМ (CETINKAYA MAKINA)

Sets: eyelets, eyelets, polyteny,all kinds of buttons, making pulling buttons and buttons. Fit all nozzles of Turkish production. Inch thread.

Weight - 4,56 kg

Production - Turkey

- Press universal lever of “Strong 22"

Sets the button, eyelets, polyteny, jeans buttons.

Width-95mm X 220mm. Height-340mm.

Weight 4.0 kg

Production: China

Comments: to all the merits of such a press is another convenience, increased distance between the center nozzle and the bed of the press. Conveniently, when it comes on the back of the jacket to install the metallic furniture, much to push the tissue product.

Notes:

- When buying the press are advised to check the alignment of the press depends on the quality of Your work.

For example to check through the nozzle to set eyelets:

Alignment is, or no alignment, possible marriage in the work.

All ruchie press DEP, TER, SEM, strong and manual presses with shock mechanism manufactured by casting of metal type cast iron.

Therefore, it is not recommended to drop the press on the floor, especially on concrete. "Dropped Microns on the floor..... .

But if this happened, not abilites, it is possible to restore the press. Even so, a thick metal plate.

Alignment of the press is not broken, the health restored. Weight increased by 50%.

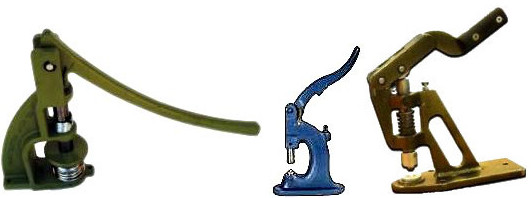

The appearance of manual presses manufactured in Germany, Italy, South Korea, China, USA, Japan, Turkey.

Reference: Media production in Turkey have 6mm inch thread at the top movable rod.

Media production China have 8mm metric thread at the top movable rod.

Purchasing a separate frame, this device can be fastened to the table and be used as a regular hand pump.

Spending presenoe time, from the hand press to make a pedal - to facilitate labor.

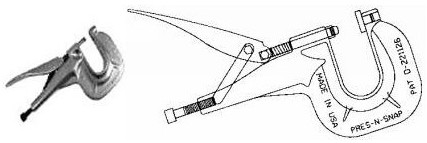

Americans all processes for installing metalfurniture combined in one device:Press-N-Snap with replaceable nozzles.

.

.

Purchasing a separate frame, this device can be fastened to the table.

And another hand press from USA Also has interchangeable heads for installation metal fittings.

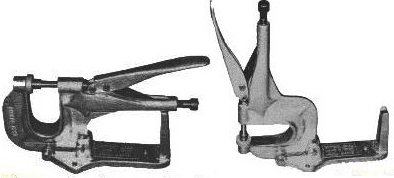

- Manual presses with shock mechanism.

Comment: These presses are designed mainly for small garment production.

Press universal D-2

Impact press for quick, easy and guaranteed workmanship pulling the buttons of the leather and fabric.

Width-200 mm X 315 mm Height-520 mm

Weight 25 kg

Production: Turkey

Comment: If you make an adapter c inch thread it is possible to install the entire range of metalfurniture.  The press handle can be deployed parallel to the table, will work even better with less power consumption.

The press handle can be deployed parallel to the table, will work even better with less power consumption.

- Press universal D-3

Sets the button, eyelets, rivets, jeans buttons, pulling the buttons. Fit all heads.

Weight - 13 kg

Production: Turkey

Comment: Great press, but heavy, if you frequently move from place to place. Covers an area 3 times larger than the press TEP-1. Must be secured to the table top or to a large metal plate with a thickness of 3 mm

- Press universal DEP-2

Press with the shock mechanism. The force of the blow 1800 kg/sq. see

It is used for setting buttons, eyelets, rivets , jeans buttons, making pulling the buttons.

Width 200 x 315mm. The height of 550mm.

Weight 25 kg

- Press universal KEP-2

Universal percussion press for cutting tissue and skin. At a corresponding additional equipment ( installation adapter for nozzles) sets of buttons, eyelets, polyteny , jeans buttons, making pulling the buttons.

Width-190mm x 340mm. Height-700mm.

Weight 45 kg

Production: Turkey

Comments: had "happiness" to use this unit. A very large weight, it is difficult to move from place to place. Inconvenient location of the working arm. But requires minimal effort when installing metal fittings.

Electro-mechanical press

Comment: designed for large-scale garment production. From 2-3 presses can be a production line. For example: one press punches holes, the second sets one part button, the third sets the second part of the button.

Universal percussion press (electric) press PDP-2000

to set eyelets, hallatrow, eyelets, buttons for jeans,, buttons.

Width-mm. The width of the table m. Height-mm.

Weight: 23 kg

Working pressure 4-12 bar. Impact strength 2000 kg/sq. see

Production: Turkey

- Press the setup ZN 90 Typical (complete set)

Device for installation of the metal hardware on jeans and other products

300 x 280 x 465 mm

The stroke of the punch 34 mm

Rated voltage 380 V

The maximum speed of the main shaft 300 rpm..

Production: Turkey

- Universal electromagnetic press MAG-01

It is used for setting buttons, eyelets, hallatrow , jeans buttons, making pulling the buttons.

The force of the blow is adjustable from 1 to 1000 kg/ sq. cm

Width-mm. Height-mm.

Weight 21 kg

Production: Turkey

-Universal motorized press BIG-01

It is used for setting buttons, eyelets, rivets, jeans buttons, making pulling the buttons.

Power punch = 350 kg/sq cm

Weight: 60 kg

Production: Turkey

- Press TT CQ-03 solenoid 3-position (3 heads rotary type)

to install any metalfurniture on apparel and leather products (buttons, polyteny, eyelets).

The universal adapter allows you to use any of the tips from the hand pump.

Laser guidance will help you to pinpoint button.

Power 220 v

Production: Ivshveymash, Russia

- Pneumatic press.

Comment: designed for large-scale garment production. From 2-3 presses can be a production line. For example: one press punches holes, the second sets one part button, the third sets the second part of the button.

Press universal pneumatic single head foam 100.600

to install buttons, eyelets, rivets, pulling buttons, cutting holes.

Working height-140mm, depth 190mm frame, the piston stroke is 40 mm, the number of -120 beats per minute. The control pedal.

Weight: 22,5 kg

Press universal pneumatic 4-way 2.4 PPU-100

3-position press to set the buttons, eyelets, hallatrow, pulling buttons, cutting holes.

Press universal pneumatic KSG 333

to install buttons, eyelets, rivets, pulling buttons, cutting holes.

Precise positioning using laser optical sign. Working pressure 2-10 bar. Requires compressed air.

Average performance - 45 cycles per minute.

The pressure rating of stem - 1 ton to 5 sq. mm.

The space between the rod and the matrix - 8 see

Power supply - 220V, 50Hz

Weight: 30 kg

Overall size: 126 x 68 x 61 see

Production: Turkey

Press universal pneumatic 1-leading 3 functional

to install buttons, eyelets, rivets, pulling buttons, cutting holes.

Precise positioning using laser optical sign.

Pneumatic and electrical control, regulation of clamp force performance - 45 cycle/min

The cylinder diameter is 100mm. Working pressure 2-8 bar. Voltage 230V. Requires compressed air.

Production: Taiwan.

- Press manual to advertising banners

Using nozzles are installed eyelets metal and aluminum with a diameter of 10, 12, 16 and 20 mm, Capacity up to 1300 PCs/shift.

Materials: fabric, leather, banner, cardboard, plastic. Thickness up to 3 mm

Weight - 4 kg