Repair products with eyelets.

- Round eyelets

Very often, manufacturers place a grommet on clothes without prior strengthening in the field installation. Accordingly eyelets eventually fall out, and more often on knitwear products. Unfortunately no regulations or Standards governing or binding the manufacturer to strengthen the place of installation metalfurniture does not exist.Moreover, the Chinese do not burden yourself with it.

And we will gladly assist repair the product.

A good result is obtained when the install eyelet diameter slightly larger than the previous standing.

Previously stood eyelets Ø 15 mm, instead of the set eyelets Ø18 mm

But the customer may ask to install the eyelet of the same size, what was previous.

You must first repair the installation position of the eyelet.

1. You (the Customer independently worked hard and was obatala hole grommet).

2. Be sure to reinforce the installation position of the eyelet thick adhesive doubleroom ( except knitted) or cloth collar.

You can do this yourself or send the customer in Atelier repair service. (This is why well, when this Studio is within walking distance).

Next: install the new eyelet, according to the scheme discussed above.

Square eyelet holes of large diameters.

In the sale of such eyelets no, so you'll have to restore again.

Rasprave belt,remove the decorative braid, remove loose eyelet.

С by bacareza straighten the cylinder eyelet.

Further improve small pliers until then, until you removed the ring eyelet

Repair the installation position of the eyelet thick adhesive doubleroom

Cut a hole of the desired diameter

Set the eyelet in place, if the rim is a little bug not allowing you to wear the ring, help thin screwdriver.  Then bocaraton ethibel outside wall of the cylinder grommets

Then bocaraton ethibel outside wall of the cylinder grommets  driving under the diameter of the nozzle.

driving under the diameter of the nozzle.

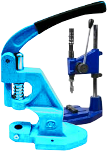

Since the respective nozzles in the presence of no, and no place to buy, use a combination of nozzles

The upper part of the nozzle Ø 18 mm, bottom part is flat ( you can use any flat pad.

Resultshowever luvers.

Of course, if you carefully work on the cylinder eyelet, the result would have been better, but time is running out, and with the inner side is not visible. The inner part of the eyelet additionally rythem small hammer

Get the desired result  With careful inspection of the visible small deformation, but the overall result is satisfactory.

With careful inspection of the visible small deformation, but the overall result is satisfactory.